|

MRC SCIENCE AND TECHNOLOGY |

|

|

MRC ENGINEERING AND MANUFACTURING |

|

|

|

Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance-nature.com |

|

News from DOM.UA -

science

|

|

28.11.2014 15:50 |

Conductive two-dimensional titanium carbide ‘clay’ with high volumetric capacitance

Michael Ghidiu, Maria R. Lukatskaya,Meng-Qiang Zhao,Yury Gogotsi & Michel W. Barsoum

Nature(2014)doi:10.1038/nature13970

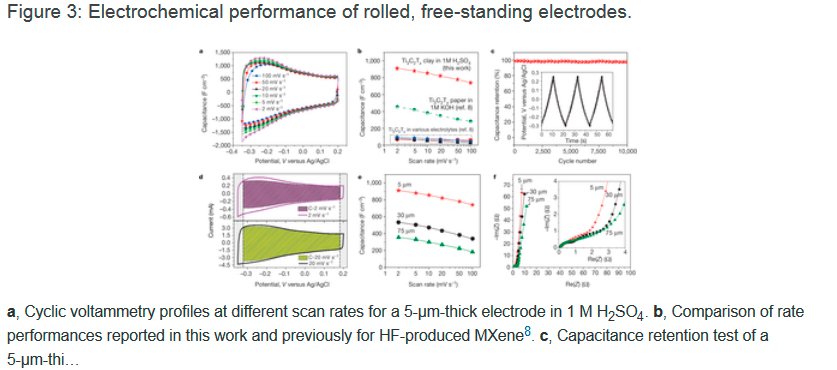

Safe and powerful energy storage devices are becoming increasingly important. Charging times of seconds to minutes, with power densities exceeding those of batteries, can in principle be provided by electrochemical capacitors—in particular, pseudocapacitors. Recent research has focused mainly on improving the gravimetric performance of the electrodes of such systems, but for portable electronics and vehicles volume is at a premium. The best volumetric capacitances of carbon-based electrodes are around 300 farads per cubic centimetre; hydrated ruthenium oxide can reach capacitances of 1,000 to 1,500 farads per cubic centimetre with great cyclability, but only in thin films.

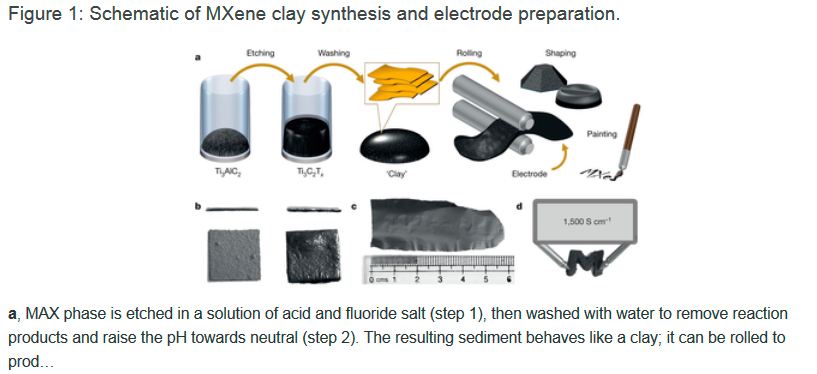

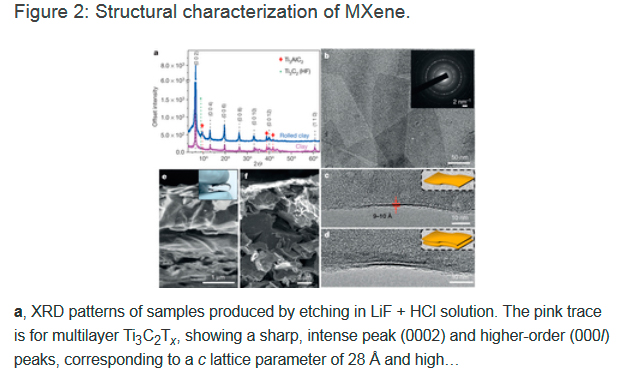

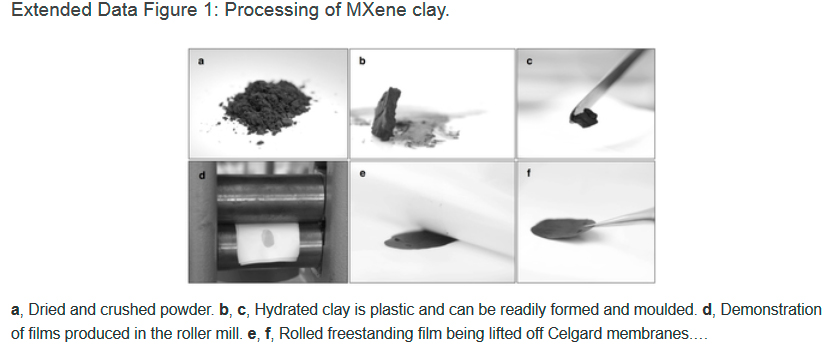

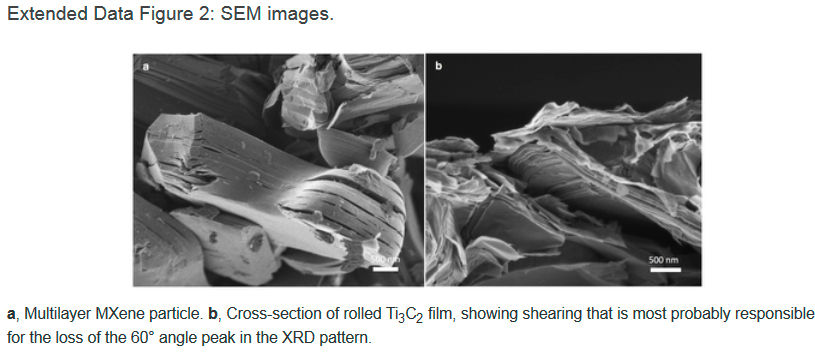

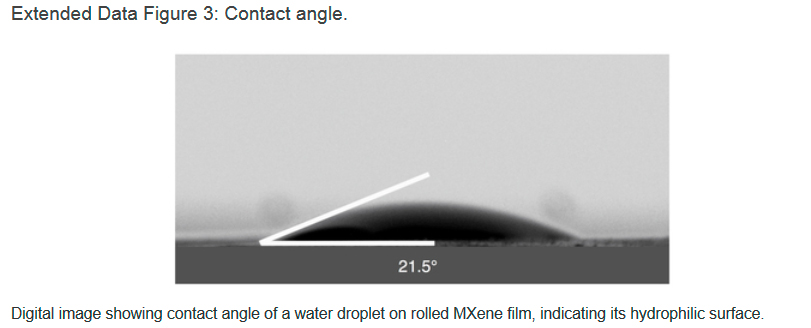

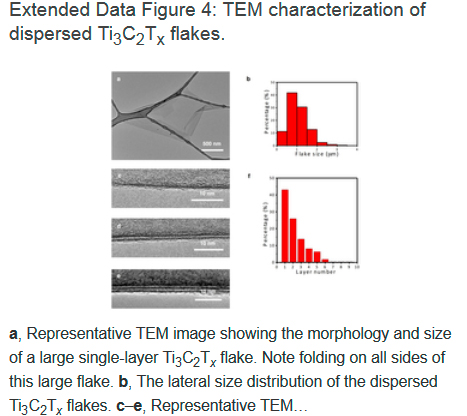

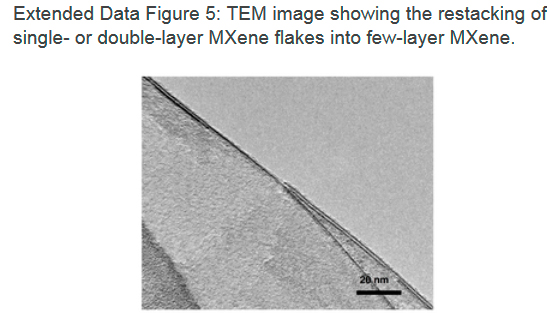

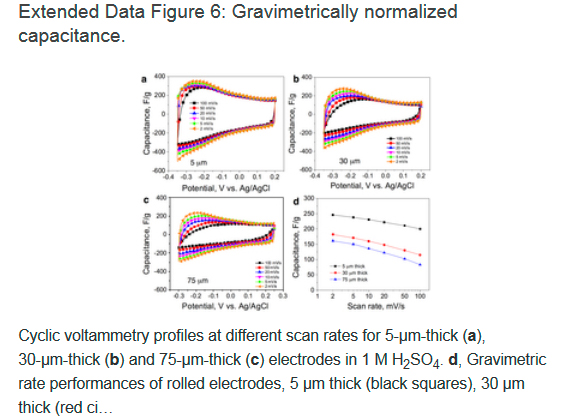

Recently, electrodes made of two-dimensional titanium carbide (Ti3C2, a member of the ‘MXene’ family), produced by etching aluminium from titanium aluminium carbide (Ti3AlC2, a ‘MAX’ phase) in concentrated hydrofluoric acid, have been shown to have volumetric capacitances of over 300 farads per cubic centimetre. Here we report a method of producing this material using a solution of lithium fluoride and hydrochloric acid. The resulting hydrophilic material swells in volume when hydrated, and can be shaped like clay and dried into a highly conductive solid or rolled into films tens of micrometres thick. Additive-free films of this titanium carbide ‘clay’ have volumetric capacitances of up to 900 farads per cubic centimetre, with excellent cyclability and rate performances. This capacitance is almost twice that of our previous report8, and our synthetic method also offers a much faster route to film production as well as the avoidance of handling hazardous concentrated hydrofluoric acid.

Source: www.mrc.org.ua

|

|

MRC ltd. / Kiev MATERIALS RESEARCH CENTRE

www.dom.ua

|

|

Science |

|

26.08.2017 02:57

Researchers described a process by which nanodiamonds — tiny diamond particles 10,000 times smaller than the diameter of a hair — curtail the electrochemical deposition, called plating, that can lead to hazardous short-circuiting of lithium ion batteries... |

04.06.2017 23:47

Join world-class nanoscientists and environmental leaders to explore how the capacity to harness molecules and atoms is accelerating spectacular inventions — including light-weight “wonder materials,” vital energy-storage technologies, and new sources of renewable energy — which promise to redefine the very future of energy... |

04.06.2017 23:39

It’s been just over five years since researchers in Drexel’s Department of Materials Science and Engineering reported on a new, two-dimensional material composed of titanium and carbon atoms, called MXene... |

11.02.2017 18:56

It’s been just over five years since researchers in Drexel’s Department of Materials Science and Engineering reported on a new, two-dimensional material composed of titanium and carbon atoms, called MXene... |

|

|

Engineering |

|

05.12.2009 19:20

Engineers of Materials Research Centre designed and produced the first in Ukraine modernized sliding door system made of polished stainless steel, used for sliding door and panel structures with tempered glass |

03.12.2009 10:20

Engineers Club of Philadelphia on behalf of the professional and technical societies in the Delaware Valley reworded Dr. S.Gucheri, the dean of Drexel Universitys CoE, the title of the 2010 Delaware Valley Engineer of the Year.

|

|

|